10 Octobre 2025 I 5. ForceYield2 project meeting

At the fifth ForceYield2 project meeting, held in Neu-Ulm in October 2025, the partners gathered in person to exchange insights and review recent progress. The discussions centered on the outcomes of the study exploring the commercialisation of synthetic biology research results, supported by comprehensive literature analyses and stakeholder interviews. Additional highlights included advances in the use of second-generation feedstocks and the ongoing planning of the reactor and experimental setup for pilot-scale operation. The meeting served as an important step in aligning technical developments with the project’s strategic goals as it approaches its final phase.

______________________________________________________________________________________

10 February 2025 I 4. ForceYield2 project meeting

During the fourth ForceYield2 project meeting, which was held online and marked the project’s halfway point, the team convened to share early outcomes, refine strategies, and align on upcoming tasks. The session also provided a useful forum to discuss challenges and keep track on key milestones and the overarching timeline. Notable highlights were the significant gains in strain development and process engineering, which are delivering encouraging results toward producing the targeted high-value products.

______________________________________________________________________________________

1 October 2024 I 3. ForceYield2 Project meeting in Berlin

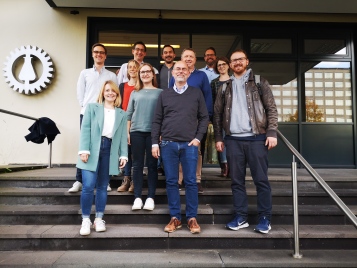

The third ForceYield2 project meeting on Octobre 1st took place at Charité Berlin and marked the successful completion if the first year. The FY2 PhD students presented their advances of the last 6 months to achieve the projects goals and all partners discussed challenges and opportunities targeting the next steps ahead.

Thanks a lot to the CHA team for organising the meeting, project dinner and lab tour!

______________________________________________________________________________________

12 May 2024 I Science award for PhD student

In May, Álvaro Salazar Quirós who works as a PhD student on the ForceYield2 project at TUM, was awarded the Wissenschaftspreis 2024 by Rotary Club Straubing and Hochschulstadt Straubing e.V. for his Master's thesis on the production of glycerol from C1-containing gases and physiological characterization of the oxygen-insensitive carbon monoxide dehydrogenase from Hydrogenophaga pseudoflava.

More details and impressions are available on LinkedIn.

Congratulations Álvaro!

______________________________________________________________________________________

7 - 8 February 2024 I 2. ForceYield2 project meeting

For the second ForceYield2 project meeting, the team including our 5th PhD student came together online to present and discuss first project results, strategies and planned tasks. The 4-hour meeting was also a great chance to discuss methodologies and check in with the overall milestone progress and work timeline.

______________________________________________________________________________________

9 - 10 October 2023 I ForceYield2 Kick-off meeting in Straubing

The ForceYield2 team had a succesfull kick-off at the Biotechnology and Sustainability Campus of the TUM in Straubing and was happy to welcome 4 new PhD students to the project. All presentations were accompanied by lively discussions and ideas how to implement the planned work in the upcoming 3 years.

Thanks a lot to the TUM team for hosting us and showing us the beautiful campus of Straubing.

______________________________________________________________________________________

15 - 17 May 2023 I ForceYield project members present at Himmelfahrtstagung on Bioprocess Engineering

The ForceYield project was present with 3 posters during this years Himmelfahrtstagung on Bioprocess Engineering which took place in Weimar and had the chance to discuss the projects achievements, challenges and vision with numerous interested researchs from academia and industry

While Lynn presented the current progress in strain engieering in her poster entiteled "Metabolic Engineering of Corynebacterium glutamicum for Efficient Xylose Utilization in Sustainable Bioprocesses", Katharina shared latest findings on bioporcess development in her poster "Adaptive laboratory evolution is a tool for non-rational strain improvement in sustainable bioprocesses". Furthermore, the recently published review paper on "Life Cycle Assessment for Early-Stage Bioprocess Development: Current state and future perspective" was presented by Esther.

______________________________________________________________________________________

16th of February 2023 I 7. ForceYield project meeting

The ForceYield team came together for a last (physical) project meeting at Charité in Berlin to exchange results, discuss current progress and plan the final steps within the project. As most PhD students were already wrapping up their work, the team took the chance to have a lovely, final dinner with the whole ForceYield team at the center of Berlin.

______________________________________________________________________________________

10th of October 2022 I 6. ForceYield project meeting in Frankfurt am Main

After 2,5 years of online meetings the ForceYield team was pleased to finally meet everyone in person in Frankfurt am Main. Lastest findings, achievements and challenges were presented and discussed. Another focus was the planning of the final year including the granted project elongation of six months. After the meeting the team took the chance to get a small tour around the old center of Frankfurt followed by a traditional dinner. The next meeting will take place in February 2023 at the Charité in Berlin.

______________________________________________________________________________________

12. - 15. September 2022 I (Bio)-Process Engineering - a Key to Sustainable Development

The ForceYield project was present at this years DECHEMA ProcessNet/BioTechNet conference in Aachen to present and discuss the ForceYield technology as well as the environmental assessment of early-stage bioprocesses with two posters. We received very positive feedback for the holistic approach of the project and explained and discussed a lot about how bioprocesses can be evaluated using Life Cycle Assessment.

______________________________________________________________________________________

10th of March 2022 I 5. ForceYield project meeting

The ForceYiel team met again online in a small round to present and discuss the current status of the project. As always, many ideas and suggestions were exchanged among the researchers and plans for the final project year were presented.

The team is still hopefull to meet again online before the end of the project and plans a 6th meeting in October 2022.

______________________________________________________________________________________

24th of September 2021 I 4. ForceYield project meeting

Time flies and ForceYield project had already its fourth project meeting. The project is progressing well and we had intersting discussions on new results and findings.

Nevertheless, the meeting had to be held once again online, therefore we are looking forward to meet in person next year in March 2022 in Frankfurt at DECHEMA.

______________________________________________________________________________________

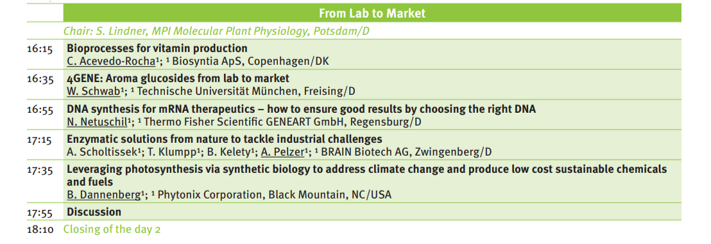

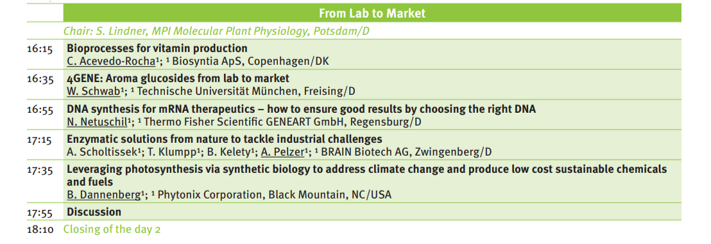

14th of September 2021 I Session "from lab to market" at GCSB

ForceYield organised a session on the topic "from lab to market" at the GSCB which was moderated by our project partner Steffen Linder (MPIMP). The five speakers introduced their companies and different application areas. The session concluded with an interesting discussion about barriers, decisions to take and opportunites of different ways from lab to markets.

______________________________________________________________________________________

10th of September 2021 I Session "from lab to market" at GCSB

The project ForceYield organises a session "from lab to market" on Tuesday, 14th of September at the German Conference on Synthetic Biology 2021.

We are exited getting to know different experiences of speakers from various industries in the synbio fields and their way from lab to market. Join us at the GCSB.

______________________________________________________________________________________

28th of April 2021 I 1st ForceYield Advisory Board Meeting

The ForceYield project is provided with external guidance and expert advice of an advisory board. Within our first advisory board meeting, we had the opportunity to introduce ForceYield and discuss our current research progress. We are happy for the support of our advisory board members Dr. Michael Zavrel - Clariant, Dr. Oliver Thum - Evonik Performance Materials GmbH and Dr. Michael Katzberg - EW Biotech GmbH.

______________________________________________________________________________________

16th of February 2021 I 3. ForceYield project meeting

Due to the pandemic the ForceYield team met once again online for a third project meeting. We were happy to see that the research is progressing fast in all work packages and the team had lively discussions on recent findings.

Our next meeting will take place in September 2021 in Stuttgart or Online.

______________________________________________________________________________________

18th of September 2020 I 2. ForceYield project meeting

Due to the pandemic the ForceYield team met online for a second project meeting. We welcomed several new PhD students to the project and were happy to see some promising first research results.

Our next meeting will take place in February 2021 in Stuttgart or Online.

______________________________________________________________________________________

31st of March 2020 I Interview with Arren Bar-Even

"Metabolism is the core of life"

4 questions to...

Dr. Arren Bar-Even, Research Group Leader Systems and Synthetic Metbolism at the Max Planck Institute of Molecular Physiology, Golm

Dr. Bar-Even, a main focus of your research team is to redesign the central metabolism of microorganisms. What do you find most fascinating about the synthetic design of those pathways?

Dr. Bar-Even, a main focus of your research team is to redesign the central metabolism of microorganisms. What do you find most fascinating about the synthetic design of those pathways?

I think that what really fascinates me is metabolism itself, even before you come to the synthetic part of it. Metabolism is basically the core of life. People tend to always relate to genetic information, DNA and so on, as the basic phenomenon of life, but I disagree. Metabolism is life. Metabolism is the concerted conversion of molecules to other molecules, responding to other stimuli but also maintaining homeostasis. This is life.

“Metabolism is life.”

The fascinating thing about metabolism that talks to me is the fact that it’s a very organized, almost mathematical process in a sense that there are very specific rules governing it. It’s easy to relate to metabolism within the framework of these rules. We are constantly trying to uncover new rules and learn from them in order to design novel metabolic pathways. This is what I find fascinating. Basically, you need two components: a basic scientific understanding of the design principles of metabolism and a more applied, engineering component that is trying to harness those understandings and design principles. Engineering pathways is not just tinkering but really thinking, designing and analyzing potential routes according to specific chemical and mathematical rules. Unlike many other biological undertakings, this is truly engineering life.

In your latest publication in Nature Chemical Biology you describe a new pathway that enables bacteria to grow on one-carbon compounds such as formate and methanol. How do those findings contribute to the sustainable production of chemicals?

Firstly, one needs to realize that almost all the things around us are composed of carbon and that this carbon mainly comes from fossil carbon sources. So, basically everything is derived from oil. I am not talking just about fuels, but also about plastics, textiles, pigments and solvents. Needless to say, the use of fossil carbon to produce compounds is not sustainable. Eventually this carbon ends up in CO2, which is not what we want. So the idea of our publication is to use CO2 to produce all those things around us. In our scenario, we create a circular carbon economy where all things start from CO2 and end in CO2 but without the net omission of CO2. This brings us to the main question: what is the best way to actually start with CO2 and end up with chemicals?

“Using agriculture to produce chemicals is probably not the best solution”

There are a lot of different approaches one can take. There are, for example, purely biological approaches, relying on agriculture or photosynthesis to fix carbon. The carbon is converted into sugar and fed to bacteria which convert the sugar into chemicals. This is one of the most common ways. The main problem with this approach is that using agricultural resources to produce chemicals directly competes with human consumption. Consequently, it threatens food security and requires the extension of agriculture, which comes at the expense of natural habitat and directly threatens biodiversity. This is why using agriculture to produce chemicals is probably not the best solution in the long run. What further complicates this approach is that it is quite inefficient. The efficiency with which plants or other photosynthetic organisms convert sunlight energy into chemical energy is actually very low.

There are a lot of different approaches one can take. There are, for example, purely biological approaches, relying on agriculture or photosynthesis to fix carbon. The carbon is converted into sugar and fed to bacteria which convert the sugar into chemicals. This is one of the most common ways. The main problem with this approach is that using agricultural resources to produce chemicals directly competes with human consumption. Consequently, it threatens food security and requires the extension of agriculture, which comes at the expense of natural habitat and directly threatens biodiversity. This is why using agriculture to produce chemicals is probably not the best solution in the long run. What further complicates this approach is that it is quite inefficient. The efficiency with which plants or other photosynthetic organisms convert sunlight energy into chemical energy is actually very low.

On the other spectrum of possibilities, one can try to convert CO2 to chemicals using purely chemical catalysis, reaching much higher energetic efficiencies. The problem there is that chemical catalysis usually requires huge facilities and operates under extreme conditions such as high pressure and very high temperatures. Furthermore, the capability of generating specific compounds is very limited. Frequently a mixture of many different compounds is obtained.

“We combine abiotic and biotic catalysis”

The approach that we are trying to implement is to combine abiotic catalysis and biotic catalysis in such a way that we get the benefits of both approaches without suffering from their drawbacks. The idea is to activate CO2 in an abiotic manner into simple one-carbon compounds. We then feed those simple, one-carbon compounds to microorganisms, which convert them into complex molecules. Both steps can be done in a very efficient and specific manner. Consequently, we have a production chain that starts from CO2, goes to one-carbon compounds using catalysis and then from the one–carbon compounds into chemicals by microbial conversion. Formic acid and methanol, which are the two one-carbon compounds we talked about in our research paper, are key because they can be produced from CO2 very efficiently.

Furthermore, they are liquid and soluble, meaning that they can be stored and transported if needed and can be easily introduced to living cells. In our publication, we engineered the bacterium E. coli in such a way that it can grow on formate and methanol. This strain can now be further engineered to produce whatever chemical you want. It could be fuel, monomers of plastic, some chemical building block, and so on. In our concept, new microbial strains will become key players in realizing a circular carbon economy.

This sounds very promising and brings me to the next question. Which pathway do you dream of? And what will it take to use this pathway for the large-scale production of bio-based chemicals in the future?

When talking about the pathway of my dreams, I am very biased. I think it’s the pathway we presented in Nature Chemical Biology. I am working on this pathway – the reductive glycine pathway – for a very long time now and I feel very optimistic about it. . There are several reasons why I really like this particular pathway. First, it is very efficient. It can be used to convert methanol or formate with minimal consumption of cellular processes, meaning that you obtain high biomass and product yields which is key for an economically and environmentally viable process.

“This pathway seems to be “plug-and-play”

But an even more important reason is that it seems like the pathway is really like a plug-and-play mechanism to assimilate one-carbon-compounds, meaning that you can implement it in multiple hosts. It’s not specific to any organism. Besides implementing the pathway in E. coli, as shown in our Nature Chemical Biology publication, we implemented the pathway in other biotechnological microbes in parallel. Hence, every lab could potentially implement this pathway in the organism of their choice and give it the ability to grow on methanol and formate to produce valuable compounds.

“There is a lot to be done for implementation”

To answer the question of what needs to be done to implement synthetic pathways in industry, I can say that there is a lot to be done. We are not yet in a place where we can deploy this technology at mass scale because there are many steps that need to be optimized. Looking at purely biological processes, microbial strains need to be further improved regarding their ability to grow on formate and methanol. Long term evolution, adaptation and optimization will be required to get the most promising strains to the full potential of the pathway. Furthermore, if we want to produce something specific from formate or methanol, we need to further engineer the strain and consequently optimize the metabolic conversion of formate or methanol to the product. And of course, if you want to use other microorganisms to produce novel compounds, you need to start with establishing the reductive glycine pathway in the new host which requires extra work.

“Getting from CO2 to formate”

On top of this there is still a lot to do in the abiotic part. As I said, our technology depends on an abiotic activation of CO2 to allow the conversion of CO2 into one-carbon compounds. These processes are being extensively researched by many labs and companies around the world and there has been a lot of progress, helping the conversion to become commercially viable. The process of getting from CO2 to methanol is relatively well developed and already commercially available. However, the process which we find even more interesting is getting from CO2 to formate. This process is still at a relatively low TRL and there is a lot of optimization to be done to get both the efficiency high, and the cost of the electrolyser as low as possible. This is why we are also collaborating with chemists and chemical companies which are focussing on CO2 conversion technologies. So optimistically, we are talking about a period of multiple years until we will be able to implement a complete production chain from CO2 to product at a commercial scale.

You are part of a national synthetic pathway project named ForceYield which kicked off recently. What’s the added value of such multi-partner projects?

I know many people that apply for funding by themselves and I know a lot of people like myself that usually apply for funding within a consortium. I think the main difference there is that if you are doing basic science than you can indeed apply for funding yourself. However, if you aim at a more applied research theme, an approach or a new product, than it’s almost impossible to conduct such a project solely by yourself. You have to collaborate; you need to have a consortium which encompasses skills beyond your own skills.

“You need experts in different kinds of aspects”

To go from an idea to a product requires a highly interdisciplinary background and very diverse skills that can address different challenges along the development of the production chain. This is also the case for the ForceYield project. We have people on board that are experts in different kinds of aspects and every one of them has to do their part so that we have a viable process in the end. Within the ForceYield team, we have experts in Metabolic Engineering that can change the internal make up of the cells. We have others that are experts in strain optimization and long term evolution of cells and others that are experts in developing and optimizing bioprocesses. A close collaboration of those disciplines is essential for the overall process. On top of this, the involvement of companies, both in the advisory board but also in the project itself, is vital to gain the right incentive and source of information that will enable us to direct the project towards an economically viable route.

Dr. Bar-Even, thank you for this interview!

__________________________________________________________________________________________

13th of February 2020 I Kick-off Meeting ForceYield project

The ForceYield project had a fruitful kick-off meeting in Golm, including lively discussions on visionary synthetic pathways and their potential for the production of bio-based chemicals.

Our next meeting will take place in the lovely town of Bielefeld in September where we will continue the ForceYield journey and will be welcoming three new PhD students in the project.

Dr. Bar-Even, a main focus of your research team is to redesign the central metabolism of microorganisms. What do you find most fascinating about the synthetic design of those pathways?

Dr. Bar-Even, a main focus of your research team is to redesign the central metabolism of microorganisms. What do you find most fascinating about the synthetic design of those pathways?  There are a lot of different approaches one can take. There are, for example, purely biological approaches, relying on agriculture or photosynthesis to fix carbon. The carbon is converted into sugar and fed to bacteria which convert the sugar into chemicals. This is one of the most common ways. The main problem with this approach is that using agricultural resources to produce chemicals directly competes with human consumption. Consequently, it threatens food security and requires the extension of agriculture, which comes at the expense of natural habitat and directly threatens biodiversity. This is why using agriculture to produce chemicals is probably not the best solution in the long run. What further complicates this approach is that it is quite inefficient. The efficiency with which plants or other photosynthetic organisms convert sunlight energy into chemical energy is actually very low.

There are a lot of different approaches one can take. There are, for example, purely biological approaches, relying on agriculture or photosynthesis to fix carbon. The carbon is converted into sugar and fed to bacteria which convert the sugar into chemicals. This is one of the most common ways. The main problem with this approach is that using agricultural resources to produce chemicals directly competes with human consumption. Consequently, it threatens food security and requires the extension of agriculture, which comes at the expense of natural habitat and directly threatens biodiversity. This is why using agriculture to produce chemicals is probably not the best solution in the long run. What further complicates this approach is that it is quite inefficient. The efficiency with which plants or other photosynthetic organisms convert sunlight energy into chemical energy is actually very low.

We are deeply saddened by the sudden loss of

We are deeply saddened by the sudden loss of